Cryo Tuning von Gitarren Teilen

Das Thema Cryo Tuning oder Cryo Aging von Gitarren Teilen ist schon seit längerem in der Gitarrenbranche angekommen. Das es zu einer mechanischen und soundtechnischen Verbesserung führt ist unbestritten, doch oft wird leider nur sehr wenig dazu erklärt, weshalb es vielen leider als Humbug erscheint. Das wollen wir hier mit einer ausführlichen Beschreibung ändern und geben sehr gerne einen Einblick in unseren Cryo Prozess.

Im Fachjargon spricht man von Cryogenic oder Tieftemperaturtechnik. Dabei handelt es sich um eine Art der Temperaturbehandlung von Bauteilen mit extrem niedrigen Temperaturen, bis knapp Minus 190 Grad Celsius. Dieses Verfahren wird im Maschinenbau schon seit geraumer Zeit angewandt. Dort dient es dazu, Bauteile allgemein verschleißfester zu machen (wie z.B. Gewehrläufe oder Motorenteile) oder aber auch die Standzeit von Werkzeugen zu erhöhen. So kann durch die Cryobehandlung die Lebensdauer von Werkzeugen (wie z.B. Schneidewerkzeuge oder Wendeschneidplatten) um 200 bis 400% erhöht werden! Dies ist natürlich auch bei unseren Gitarrenteilen ein wünschenswerter Effekt.

Bei unserem Cryo Tuning werden Bauteile während eines kontrollierten Prozesses sehr langsam und stufenweise auf Minus 180 Grad heruntergekühlt. Diese extreme Temperatur wird durch flüssigen Stickstoff erreicht, welcher aber dank der dafür vorgesehenen Maschine nie direkt mit den Bauteilen in Berührung kommt und diese dadurch nicht beschädigen kann. In der Maschine wechseln sich kurze Kühl- und Aufwärmphasen innerhalb eines speziell darauf abgestimmten Prozesses immer wieder ab. Nach über 20 Stunden werden die Bauteile langsam wieder auf Raumtemperatur gebracht und können entnommen werden. Also ein sehr langwieriger, komplexer und vor allem auch kostenintensiver Prozess.

Aber was passiert denn nun genau innerhalb des Materials? Dafür machen wir einen kleinen Ausflug in die Physik, welche uns das Verfahren eindeutig erklären kann und zwar auf atomarer Ebene. Die Physik sagt uns, dass es auf das Metallgefüge ankommt! Genauer gesagt geht es um die Karbide im Metall. Karbide sind Metall-Kohlenstoff-Verbindungen, welche bei der Herstellung des Metalls, genauer gesagt bei dessen Erstarrung, entstehen. Diese sind meist ungleichmäßig im Metall verteilt und beinträchtigen dabei die Materialeigenschaften. Durch die Cryobehandlung kommt es nun zu mikrostrukturellen Veränderungen im Metall und es werden die Karbide neu geordnet, so das diese gleichmäßig im Metall verteilt werden. Dadurch erhalten wir verschleißfestere Bauteile und auch im Bezug auf die Tonentfaltung können wir eindeutig eine Verbesserung beim Ansprechverhalten, dem Sustain und der Ausgewogenheit im Klang feststellen. Bauteile weisen nach der Behandlung die gleichen Eigenschaften auf, wie Jahrzehnte alte und eingeschwungene Teile. Deshalb können wir mit Teilen aus unserer Silverback Vintage Serie, die Cryobehandelt wurden, neben den vintage korrekten Maßen und Materialien auch DEN vintage korrekten Ton liefern!

Wir sind der einzige Hersteller weltweit, der Tremolo Federn erfolgreich einem Cryo Tuning unterzieht. Die Auswirkungen spürt und hört man eindeutig. Überzeugt Euch selbst, nicht umsonst geben wir 60-Tage Mon(k)ey Back Garantie auf all unsere Produkte! Weitere Cryo behandelte Produkte folgen natürlich.

Hier gehts zu unseren Pre-CBS Vintage Tremolo Springs.

Ebenso sind wir weltweit der einzige Hersteller der Gitarren Saddles / Saitenreiter einem Cryo Tuning unterzieht.

Hier gehts zu unseren Cryo Tuned Saddles

Unsere Gitarren Mechanik Holz Buttons

-

Small German Ebenholz Gitarren Mechanik Flügel / Tuner Buttons / Knöpfe

Normal price From €27,90Normal pricebasic price / pro -

Big German Ebenholz Gitarren Mechanik Tuner Buttons / Flügel / Knöpfe

Normal price From €27,90Normal pricebasic price / pro -

Big Vintage Kidney Bean Ebenholz Gitarren Mechanik Tuner Buttons / Flügel / Knöpfe

Normal price From €27,90Normal pricebasic price / pro -

Small German Tamarindenholz Gitarren Mechanik Flügel / Tuner Buttons / Knöpfe

Normal price From €27,90Normal pricebasic price / pro

Unsere Monkey Locks - Locking Tuners

-

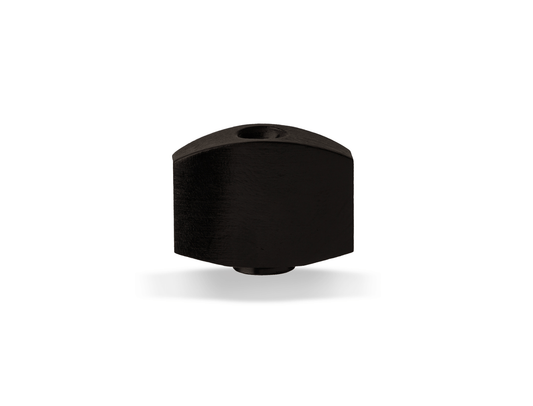

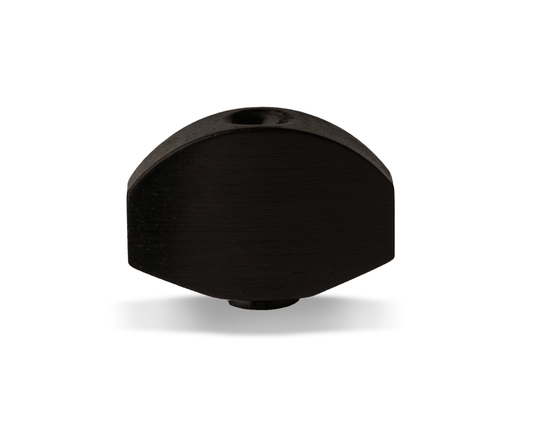

Einzelne - Monkey Lock - Locking Tuner - Gitarren Klemm Mechanik - Big German Metal Button

Normal price From €11,90Normal pricebasic price / pro -

Einzelne - Monkey Lock - Locking Tuner - Gitarren Klemm Mechanik - Small German Metal Button

Normal price From €11,90Normal pricebasic price / pro -

Einzelne - Monkey Lock - Locking Tuner - Gitarren Klemm Mechanik - Megalight Monkey Grip Button - Small German

Normal price From €14,20Normal pricebasic price / pro -

Einzelne - Monkey Lock - Locking Tuner - Gitarren Klemm Mechanik - Celtic Megalight Monkey Grip Button - Small German

Normal price From €14,20Normal pricebasic price / pro

Unsere Bass Mechaniken

-

Einzelne Bass Mechanik - Slinky Metal Button

Normal price From €8,90Normal pricebasic price / pro -

Einzelne (1 L) Silverback Vintage Bass Mechanik Prejazz in Schwarz - Clover Leaf Buttons

Normal price €12,50Normal pricebasic price / pro -

Einzelne (1 R) Silverback Vintage Bass Mechanik Prejazz in Schwarz - Clover Leaf Buttons

Normal price €12,50Normal pricebasic price / pro -

Einzelne (1 L) - Silverback Vintage Bass Mechanik Prejazz in Nickel - Clover Leaf Buttons

Normal price €12,50Normal pricebasic price / pro